1.0

Introduction

Significant concern exists over relatively high cost of electricity for citizens and businesses worldwide, which imposes a financial burden and impairs countriesf ability to compete effectively. On the other hand, there is a significant cost to protect our environment. A component of that cost is electricity. New environmentally preferred technologies and strategies are needed to produce and deliver electricity at lower cost and decreased environmental impacts. The potential problem is further compounded by a fact that systems reliability and the cost of electricity are adversely affected by existing large inventory of outdated steam power plants. Moreover, it is further amplified by a need for new cost-effective pollution control technologies needed to reduce the health and environmental impacts from power plant emissions. Therefore, a pressing need exists to develop superior, but economical methods to produce electricity while reducing the wood and green waste landfills with the state-of-the-art control emissions of fine particles and vapor-phase aerosols/toxics.

Integrated Biomass Gasification Combined Cycle (IBGCC) systems replace the traditional combustor with a gasifier and gas turbine. Exhaust heat from the gas turbine is used to produce steam for a conventional steam turbine. The gas and steam turbines operate together as a combined cycle.

1.1

How

IBGCC Works

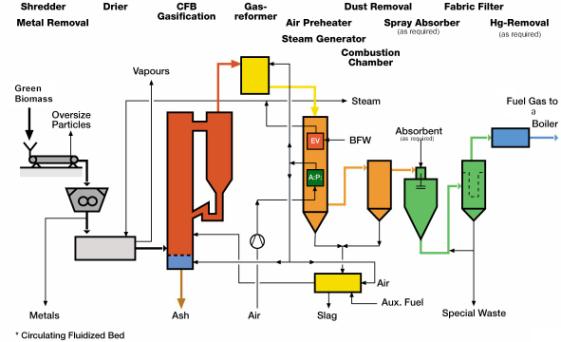

IBGCC

systems are extremely clean, and much more efficient than traditionally fired

systems. The technology is based

on an advanced technology - a gasifier used in place of the traditional combustor

- coupled with a key enabling technology, the advanced gas turbine. The resulting system is an integrated

biomass gasification combined-cycle (Figure 1) configuration that provides high

system efficiencies and ultra-low pollution levels.

Figure 1. Integrated Biomass Gasification Combined Cycle Power

Generation Concept.

In an IBGCC system, biomass is converted into a gaseous fuel, which, when cleaned, is comparable to natural gas. The hot gas is further cleaned by an advanced cleanup process before being burned in the gas turbine to generate electricity. Exhaust heat from the gas turbine is used to produce steam for a conventional steam turbine, resulting in the two cycles of electric power generation.

The IBGCC systems that are currently available commercially have demonstrated exceptional environmental performance. Unparalleled success has been shown in sulfur dioxide (SO2) removal, nitrogen oxides (NOx) reduction, and particulate removal. The result SO2 and NOx emissions are less than one-tenth of that allowed by New Source Performance Standards limits.

At the same time, IBGCC efficiency levels top 40 percent. The efficiency level of a power plant is measured by the amount of electrical energy produced per amount of coal energy used to create it, and the baseline efficiency of a conventional coal-fired plant is at best 34 percent. From 1950 until today, conventional power plants have managed to increase efficiency slowly from 25 percent to this level. IBGCC offers a step up in efficiency improvement.

1.2

Biomass

Syn-Gas For Use In Combustion Turbines For Electricity Generation

In the mid-1970s, gasification of biomass was seen as a process route to alternative fuels for power generation and methanol production. In the 1980s however, lowered expectations on future oil prices created an unfavorable climate for alternative fuels and much of the development work on gasification was stopped. Yet, since 1989, a new wave of developments for biomass gasification was started.

The IBGCC technology for generation or stand-alone power applications in many instances looks promising in being able to produce electricity at a lower cost than most alternatives. For example, green waste could present a favorable target for near-term applications of IBGCC technologies. Depending on the choice of gas turbine technology and the extent to which the green waste can be used, the amount of electricity that can be produced could be rather substantial. Globally, an estimated 50,000 MW of IBGCC capacity could be supported using the green waste as fuel.

1.3

IBGCC

Power Generation Concept.

Biomass

fuel is very often available at low cost or may be available even free. Reason for this is that in come cases

wood wastes can only be disposed of at additional cost, and then the owners

will welcome someone willing to remove them from the premises. Thus, there is an inexpensive,

abundant, and renewable feedstock.

In

order to introduce biomass as a source of electricity and chemicals on a large

scale, efficient and competitive conversion techniques are needed. Some of the advanced conversion

techniques that are being developed include: fermentation for the production of

methanol, pyrolysis to produce charcoal and crude bio-oil and

gasification.

In the process of gasification, biomass is heated in the presence of a relatively small amount of air, oxygen, or steam. This results in partial combustion of the biomass. The resulting product depends on the kind of gasification medium used. Gasification with air results in a low calorific gas that can be used in gas engines or turbines. Gasification with oxygen results in a high quality mixture of carbon monoxide and hydrogen called syn-gas. Syn-gas can be used as a fuel or as a base chemical for the production of synthetic petrochemicals. Gasification with steam is more commonly called reforming and results in a syn-gas rich with hydrogen.

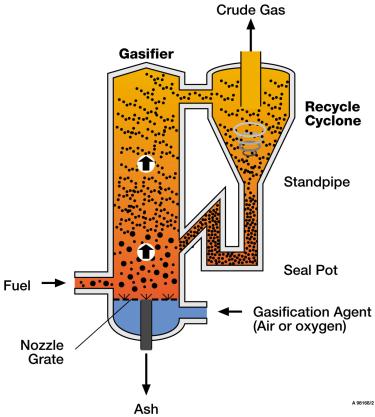

The synthetic process utilizes a pyrolytic reactor (typically a CFB unit, Figure 2) operating as a gasifier by injecting air or pure oxygen into the reactor core to completely burn the biomass to ash. The energy contained in the biomass is released in the gasses formed. After purification the syn-gas, hydrogen and carbon monoxide in a 2 to 1 ratio, is altered by catalysts under high pressure and heat, to form methanol. This method will produce about 100 gallons of methanol per ton of feed material.

Gasification has been practiced many years already. Until the 1950's, coal gas supplied many houses in European cities with fuel for cooking and heating. Ultimately, the coal gas factories were shut down because they were dangerous and dirty. Biomass gasification was also used during the 1930's and 1940's for vehicles.

However,

the application of biomass gasification for use in highly efficient, clean,

modern engines still poses considerable difficulties. The demands of these engines with respect to gas quality are

extremely high, thus the demands to the gasifier technology are also very

high.

Figure 2. Typical Biomass Gasification System

Schematic.

Furthermore, the choice of biomass is also an important aspect of implementing biomass gasification. It is desirable to obtain the feedstock for the gasifier from the vicinity of the gasifier. Therefore, especially in urban areas, there may be large quantities of ggreenh type of biomass available in the direct surroundings of the gasifier. On the other hand, however, the gasifier should be able to handle different kinds of biomass. This requires a methodology to characterize the various types of biomass and to predict the gasifier behavior from this characterization.

1.4

IBGCC

as Environmentally-Preferred Advanced Power Generation

Activities

within the electric generation sector can have substantial benefits on the

overall emission of greenhouse gases.

Changes in generation technology and in how generation is operated and

maintained and where on the grid it is located can have measurable beneficial

effects both on operating costs and on greenhouse gas emissions.

There are

three broad strategies that utilities can pursue when contemplating reducing

greenhouse gas emissions through changes in generation:

q

Improve

the efficiency of existing capacity

q

Repower or

replace generation with more efficient generation; and

q

Repower or

replace generation with generation that uses lower-carbon or no-carbon fuels.

These efficiency improvements will frequently result in both lower-cost operations and decreases in greenhouse gas emissions. Repowering existing generation or replacing it with generation that is more efficient can reduce emissions of greenhouse gases and air pollutants compared to operating the original equipment without change. Generation that is more efficient means less fuel consumed per kWh of electric output. Repowering or replacing generation with generation that uses lower-carbon or no-carbon fuels provides an additional greenhouse gas reduction benefit.

The rates

charged by any electric utility shall be such that the utility is encouraged to

make investments in, and expenditures for, all cost-effective improvements in

the energy efficiency of power generation, transmission and distribution.

The

efficiency improvements will frequently result in both lower-cost operations

and decreases in greenhouse gas emissions. Repowering existing generation or replacing it with generation

that is more efficient can reduce emissions of greenhouse gases and air

pollutants compared to operating the original equipment without change. More efficient generation means less

fuel consumed per kWh of electric output.

Repowering or replacing generation with generation that uses

lower-carbon or no-carbon fuels provides an additional greenhouse gas reduction

benefit.

The Integrated Biomass Gasification Combined Cycle (IBGCC) Power Generation concept:

q is environmentally superior to conventional wood fired power plants and can be designed to meet the most stringent regulations;

q surpasses thermal efficiencies of existing gconventionalh technologies;

q could generate power at lower costs.

2.0

Biomass

Gasification

Biomass fuel is very often available at low cost or may be available even free. Reason for this is that in some cases wood wastes can only be disposed of at additional cost, and then the owners will welcome someone willing to remove them from the premises. Thus, there is an inexpensive, abundant, and renewable feedstock.

In order to introduce biomass as a source of electricity and chemicals on a large scale, efficient and competitive conversion techniques are needed. Some of the advanced conversion techniques that are being developed include: fermentation for the production of methanol, pyrolysis to produce charcoal and crude bio-oil and gasification.

Pyrolysis is the technique of applying high heat to organic matter (lignocellulosic materials) in the absence of air or in reduced air. The process can produce charcoal, condensable organic liquids (pyrolytic fuel oil), non-condensable gasses, acetic acid, acetone, and methanol. The process can be adjusted to favor charcoal, pyrolytic oil, gas, or methanol production with a 95.5% fuel-to-feed efficiency.

Sixty-eight percent of the energy in the raw biomass is contained in the charcoal and fuel oils made at the facility. The charcoal has the same heating value in Btu as coal, with virtually no sulfur to pollute the atmosphere. The pyrolytic fuel oil has similar properties to no. 2 and no. 6 fuel oil. The remaining energy is in non-condensable gases that are used to co-generate steam and electricity. Every ton of biomass converted to fuels in this manner produces approximately 27% charcoal, 14% pyrolytic fuel oil, and 59% intermediate-Btu gas.

Chemical decomposition through pyrolysis is the same technology used to refine crude fossil fuel oil and coal. Biomass conversion by pyrolysis has many environmental and economic advantages over fossil fuels, but coal and oil production dominates because costs are kept lower by various means including government protection.

2.1

General

Gasification has been practiced many years already. Until the 1950's, coal gas supplied many houses in European cities with fuel for cooking and heating. Ultimately, the coal gas factories were shut down because they were dangerous and dirty. Biomass gasification was also used during the 1930's and 1940's for vehicles.

However, the application of biomass gasification for use in highly efficient, clean, modern engines still poses considerable difficulties. The demands of these engines with respect to gas quality are extremely high, thus the demands to the gasifier technology are also very high.

The most important problems encountered in biomass gasification are: tar formation, the dynamic behavior of the gasifier and the choice of biomass. Although the bulk of the gas produced in the gasifier consists of carbon monoxide, hydrogen, and nitrogen, there will also be small amounts of hydrocarbons in the gas. Some of these hydrocarbons will condensate or polymerize as the gas cools after leaving the gasifier or as the gas is pressurized in the engine. These deposited hydrocarbons are known as tar. Usually tar deposition results in failure of the engine. When tar is removed in a cleaning system behind the gasifier, one obtains a toxic residue that must be disposed off. Preventing tar formation and removing tar cleanly present great challenges in developing biomass gasification.

Biomass contains about 70% volatiles. This is much more than coal. Moreover, biomass can contain a lot of water, whereas coal is usually relatively dry. In fluidized bed gasifiers, this results in much lower carbon hold-ups in the reactor. This has an immediate impact on the dynamics of the system. The fluctuations in gas volume and composition leaving a fluidized bed biomass gasifier are much larger and much faster than with a coal gasifier. The impact of these fluctuations on the rest of the system (such as gas cleaning and the engine) is still largely unknown.

Furthermore,

gasification can be broadly defined as the thermochemical conversion of a usually

solid or liquid carbon-based material into a combustible gaseous product. In comparison, "combustion"

may be defined as the rapid high-temperature oxidation (burning) of a solid,

liquid, or gaseous material.

Thermochemical conversion and combustion (sometimes called

"incineration") are two different chemical processes. They share, however, two primary

similarities. First, both

processes are thermal. Second,

combustion (incineration) may or may not occur during thermochemical

conversion. Combustion during

thermochemical conversion, however, is usually the last phase of the process,

and applies to the residue char that was generated during previous stages.

Just as

there are differences between chemical reactions, which occur during

thermochemical conversion, and combustion, so also the chemical products that

are generated are different. The

main product of combustion is heat, whereas the main product of gasification is

medium energy gas. This gas can be

utilized directly as a fuel for power generation in gas turbines, etc. or as a feedstock for the production of

chemicals otherwise produced from fossil fuels. "The third type of directly heated reactors, fluidized-bed

gasifiers, seems to be the most appropriate for biomass utilization."

In the process of gasification, biomass is heated in the presence of a relatively small amount of air, oxygen, or steam. This results in partial combustion of the biomass. The resulting product depends on the kind of gasification medium used. Gasification with air results in a low calorific gas that can be used in gas engines or turbines. Gasification with oxygen results in a high quality mixture of carbon monoxide and hydrogen called syn-gas. Syn-gas can be used a fuel or as a base chemical for the production of synthetic petrochemicals. Gasification with steam is more commonly called reforming and results in a syn-gas rich with hydrogen.

2.1.1 Thermal Processing

At

temperatures in excess of 600 ºC, the volatile pyrolysis products undergo

secondary gas-phase reactions that closely resemble the hydrocarbon cracking

reactions used in the petrochemical industry for manufacturing ethylene and

propylene.

Methanation:

![]()

Similar

cracking (thermal decomposition) and reforming reactions (the opposite of

methanation) involving higher hydrocarbons also occur. During this step, condensable pyrolysis

products (tars and oils) and primary char decompose further (crack) into

non-condensable gases, secondary char and residual tars and oils.

In the final step, the char reacts endothermically with steam (and to lesser extent with carbon dioxide) to produce mainly carbon monoxide and hydrogen. Char reactions require higher temperatures than pyrolysis, and for biomass only proceed rapidly above approximately 700 ºC. In most gasifiers developed to date, some of the char residue and/or biomass is burned by adding air or oxygen (which generates heat needed for the endothermic pyrolysis and char gasification reactions).

Again,

comparing the two processes, combustion and thermochemical conversion, it is

relatively easy to observe the differences. During oxidation, components of a material react with oxygen. In turn, during thermochemical

conversion different chemical reactions occur. During pyrolysis, a chemical change occurs in the material,

caused by heat in the absence of oxygen.

During the next step, char, tars, and oils generated during pyrolysis

undergo further thermal decomposition (again in the absence of oxygen). In the final step, char reacts with

steam. At this point air or oxygen

may be added to burn char and provide heat for pyrolysis and gasification

reactions.

The

process can be accomplished in an oxygen-controlled atmosphere (termed partial

oxidation), but also in a process that does not require oxygen (termed

pyrolytic gasification). The

gasification process is endothermal, which means that a certain amount of heat

has to be provided for the process to occur. During partial oxidation, oxygen in the process (either pure

or from the air) is the source of heat for the reaction. Therefore, the process is called

"direct gasification.h During

pyrolytic gasification (no oxygen present), a source of heat has to be provided

externally, so the process is also called "indirect gasification.h "Gasification systems emit fewer

gaseous pollutants than modern incinerators and produce liquid and solid wastes

that are non-hazardous."

Air gasification and oxygen gasification are partial oxidation processes. The product of air gasification is a low energy gas (below 200 Btu), which results from nitrogen content in the air. Currently, this gas is only suitable as a fuel (close-coupled to gas/oil boilers) for operation of diesel or spark engines and for crop drying. Oxygen gasification used to be preferred method of gasification in methanol synthesis. The gas product of oxygen gasification is a medium energy gas (300-600 Btu), which requires a minimal cleanup. Synthesis gas (produced from oxygen gasification) can be converted into methanol, used directly for the production of steam in gas-fired boilers, or for peaking turbines in power generation. In turn, indirectly heated processes do not use oxygen as a gasifying medium, but steam or hydrogen is employed. However, they also generate medium energy gas.

Finally, the choice of biomass is also an important aspect of implementing biomass gasification. It is desirable to obtain the feedstock for the gasifier from the vicinity of the gasifier. Therefore, especially in urban areas, there may be large quantities of ggreenh type of biomass available in the direct surroundings of the gasifier. On the other hand, however, the gasifier should be able to handle different kinds of biomass. This requires a methodology to characterize the various types of biomass and to predict the gasifier behavior from this characterization.

2.2

Biomass

Gasification Technology Review

Biomass

gasification is a process that converts wood and/or green waste into a

synthetic gas composed mainly of carbon monoxide and hydrogen. Biomass can be gasified in various ways

by properly controlling the mix of biomass, oxygen, and steam within the

gasifier. There are also several

options for controlling the flow of biomass in the gasification section (e.g.,

fixed-bed, fluidized-bed, and entrained-flow systems).

2.2.1

gDirecth

Gasification

Directly

heated gasification systems have an operational history of dating back over one

hundred years. They emerged from

coal gasification technologies.

The drawback of oxygen-blown gasifiers is that they require high purity

oxygen.

Oxygen,

manufactured on-site or bought from a producer, will significantly increase

gasification costs. In addition,

oxygen-generating plants consume a great amount of electricity.

There are

three different types of directly heated gasifiers: fixed bed, entrained-bed,

and fluidized bed (see Figure 3).

The fixed bed gasifier is the simplest and was the first to operate

successfully on coal and municipal solid waste (MSW). Two types of fixed-bed gasifiers have been built: updraft

and downdraft. In an updraft

process, the feed is fed from the top and drops to the bottom, while the oxidant

and the gases flow upward counter-current to the feed.

In a downdraft reactor, oxidant and feed are fed from the top, and the gases flow concurrent with the feed. The solid residue from the gasifier may be either slag or dry ash. Dry ash gasifiers must keep the temperatures below ash fusion temperatures (1000 – 1300 ºC). Slagging gasifiers melt the residue into molten slag and require much higher peak temperatures. The feed moves continuously downward, so the fixed gasifier is also known as a "moving bed" gasifier. No fixed-bed gasifiers were ever considered for fuels production, as they produce a large amount of oils and condensable gases that would require cleanup.

Figure 3.

gDirecth Gasification Processes.

Entrained-bed

gasifiers are usually oxygen-blown and are characterized by very high temperatures,

so that a molten slag residue is formed.

The bottom combustion zone can reach 2000 ºC. The main aim of these gasifiers is to gasify the feed

rapidly (i.e. in seconds). This is

quite different from some fixed bed gasifiers, which have residence times of

over one hour (for coal feeds).

Oxygen and steam are blown into the gasifier and entrain the feed. Due to the fast reaction times,

entrained-bed gasifiers can have high throughput rates at modest reactor sizes,

especially when operating at high pressures.

Despite

many advantages such as complete carbon conversion rates and elimination of

tars and oils from the product gas, they have drawbacks that deem them unsuitable

for biomass. The most important of

them is a need to pulverize feedstock (100-600 microns), which requires large

capital and energy inputs.

Moreover, biomass does not require as high temperatures as entrained-bed

gasifiers are made for. Recently,

however, due to the potential hazards of incinerator ash, slag rather than ash

has become the preferable residue from gasification and incineration

systems. For this reason, this

type of gasifier is often preferred.

The third

type of directly heated reactors, fluidized-bed gasifiers, seems to be the most

appropriate for biomass utilization.

The reason is their ability to accept feeds of different sizes and densities,

their low tar/oil input and good solids mixing. Crushed feedstock is fed through the side of the vessel and

is mixed and suspended by oxygen or air blown from the bottom. Sand or other inert materials can be

used in the bed to carry heat.

Typical operating temperatures for fluidized-bed gasifiers are 900-1000

ºC.

2.2.2

Indirect

Heat Systems for Biomass Applications

Indirectly heated gasifiers are heated externally in various

ways. The higher reactivity of

biomass and biomass wastes compared to coal allows these new gasification

systems to operate at lower temperatures.

They are potentially cost effective and efficient, but are in the early

stages of commercial development.

They usually operate at temperatures 600 – 900 ºC. Reactor temperatures are lower than ash

fusion points, so that clinkering is prevented. The product gas that is formed during the process is usually

of medium energy value, avoiding expensive oxygen.

The heart of the BGS is the Lurgi CFB Gasifier (Figure 4). The CFB gasification unit consists of a vertical, cylindrical, refractory lined vessel with recycle cyclone, bottom ash cooling, and if required, dry ash removal and wet gas scrubbing systems. The CFB gasifier operates in a mode between the classical bubbling bed and pneumatic transport reactor. Under those conditions the slip velocity between solids and gas (or the velocity differential) is highest, leading to maximum heat and mass transfer between gas and solids, thus requiring the smallest reactor diameter of all fluidized bed principles. The CFB unit comprises a reactor, in integral recycle cyclone and a seal pot with connecting lines/pipes. Because of the high velocities, (5-8 m/s) almost all solids are entrained and discharged from the reactor. The solids separated in the cyclone are returned to the reactor via the seal pot. The gasification agent, air is fed as primary air through the nozzle grate and as a secondary air at a level above the fuel supply point. Biomass is introduced into the reactor near its bottom. The only fuel preparation required is size reduction to below 25-50 mm and removal of major iron and metal components.

The gasification reactions begin immediately as the fuel is fed in the reactor[1]. A uniform bed temperature profile is established because of the high recirculation rate of the bed material and the high heat exchange efficiency in the CFB system. This ensures rapid heating of the incoming fuel. Significant expansion of the fluidized bed is a further important effect of the high recirculation rate.

There is no so-called freeboard, which means that the bed material is uniformly distributed inside the reactor, having advantages of a high C conversion rate of the fuel (C content of the ash < 2%) and a low hydrocarbon content in the gas. This is of particular importance if the gas is to be dedusted and cleaned downstream. The gasification process takes place at pressures slightly above ambient (approximately 1.3 bar) and at temperatures between 800 and 950 C depending on the reactivity of the fuel. The product gas leaves the cyclone at reactor temperature with a dust content of about 40 to 60 g/Nm3.

The following fuel gas analysis (Table 1) based on gtypicalh biomass/wood gasification with air is typical:

Table 1. gTypicalh syn-gas chemical analysis.

|

Component |

Volume, % |

|

CO |

22 |

|

H2 |

13 |

|

CH4 + hydrocarbons |

4 |

|

H2O |

7 |

|

CO2 |

12 |

|

N2 |

42 |

|

HHV |

Approx. 150 Btu/scf |

As it was noted before, the Lurgi CFB gasifier operates at

near atmospheric pressure and is therefore well suited for most of the

applications[2].

Figure

4. Lurgi Gasifier.

2.3

CFB

Gasification Features and Technology

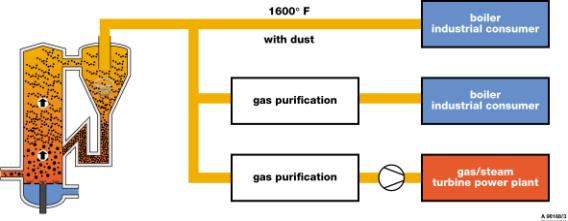

In the CFB gasifier, the wood or biomass is converted into a medium Btu gas using steam and oxygen as gasification agents. Next, the gas generated is cooled and fed to the gas purification system where gforeignh components and substances are removed. The clean fuel gas is now ready to be fed to either an industrial user or to a combustion turbine (CT) (Figure 5).

The technology is featuring the following:

q Acceptance of a wide variety of feeds, such as wood, straw, nutshells, sludge, etc. (including gvery oldh wood, i.e. pit and coal);

q Low specific investment cost already at very small unit sizes, i.e. highly suitable for small and medium sized industrial plants.

2.3.1

The Gasification Concept

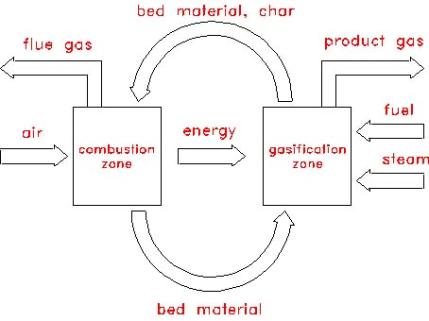

The basic idea of the

gasifier concept is to divide the fluidized bed into two zones, a gasification

zone, and a combustion zone.

Between these two zones, a circulation loop of bed material is created

but the gases should remain separated.

The circulating bed material acts as heat carrier from the combustion to

the gasification zone. The

principle is shown graphically in Figure 6.

Figure 5. Typical uses of the

Biomass Gasification Concept.

The fuel is fed into the

gasification zone where it is gasified with steam. The gas produced in this zone is therefore nearly free of

nitrogen. The bed material,

together with some charcoal, circulates to the combustion zone. This zone is fluidized with air and the

charcoal is partly burned. The

exothermic reaction in the combustion zone provides the energy for the

endothermic gasification with steam.

Therefore, the bed material at the exit of the combustion zone has a

higher temperature than at the entrance.

The flue gas will be removed without coming in contact with the product

gas. With this concept, it is possible

to get a high-grade product gas without use of pure oxygen. In greal lifeh this process can be

realized with two fluidized beds connected with transport lines or with an

internally circulating fluidized bed.

Figure 6. Basic idea of the gasification process.

In a commercial CFB unit (Figure 4), solid biomass is surrounded by sand heated to 1800-1900 F, which converts the biomass into gas and residual char in a fluidized-bed reactor at 1500-1600 F. Sand is used to carry the biomass and the char and to distribute the heat. Using sand as a heat carrier keeps out the air. This results in a better quality fuel gas. A second reactor (zone) combusts the char to heat the sand. Remaining traces of condensable matter formed during gasification are removed in a chamber where a catalyst "cracks" and converts them into fuel gas. The clean biogas is then pressurized before it reaches the gas turbine

3.0 IBGCC Power Generation Concept

This technology can be applied to organic residues from any

source, such as sorted urban waste, peat moss and straw, as well as wastes from

various industries, such as wood, oil, rubber, and agro-food. It involves three main stages:

q preparation and conditioning of the raw material (reduction of biomass particle size and humidity adjustment);

q biomass gasification in bubbling fluidized bed reactor;

q cold or hot purification of the producer gases, depending on proposed use.

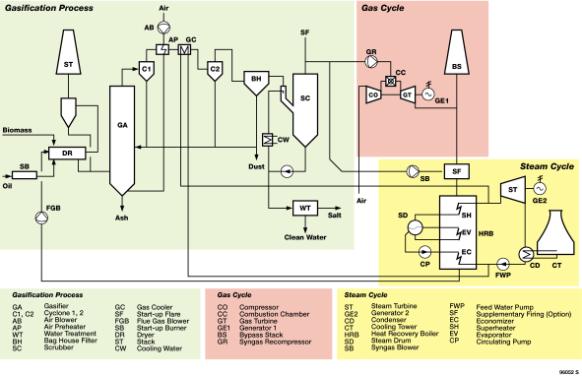

Figure 7 shows a typical IBGCC process flow. Plant efficiency can be improved further by: injecting the nitrogen from the air separation unit into the fuel gas prior to the gas turbine and utilizing air from the gas turbine/compressor in the air separation unit (see dotted lines).

The gas obtained can then be used for energy production, either alone or in combination with natural gas (Figure 5). The syn-gas leaving the gasifier must be cleaned (to very high levels of removal efficiencies) of gaseous compounds and particulates. Cleanup occurs after the gas has been cooled, which reduces overall plant efficiency and increases capital costs, or under high pressure and temperature (hot-gas cleanup), which has higher efficiency.

After the fuel gas has been cleaned, it is burned and expands in a gas turbine. Steam is generated and superheated in both the gasifier and the heat recovery unit downstream from the gas turbine. The fuel gas is then directed through a steam turbine to produce electricity.

Figure

7. IBGCC Process Flow.

3.1

Integrated

Biomass Gasification Combined Cycle

IBGCC combines both steam and gas turbines ("combined cycle"). Depending on the level of integration of the various processes, IBGCC may achieve 40 to 42 percent efficiency.

At the core of the entire project is a fully conventional, highly efficient, combined cycle power plant capable of reliable operation on natural gas or other fuel. The addition of the Integrated Biomass Gasification Combined Cycle (IBGCC) converts biomass to a clean fuel gas, which is burned in the advanced, high efficiency combustion turbine (Figure 8).

For

increased efficiency, exhaust from the turbine is also used to produce steam,

which is expanded through another turbine. The superheated, high-pressure steam drives the condensing

steam turbine-generator, which produces additional power without using additional

fuel.

The result is a highly efficient unit with multiple fuel capabilities to choose from - whichever fuel is more economically priced at the time.

3.1.1 Components

An integrated biomass

gasification combined cycle plant encompasses three processes: (1)- Gasification,

(2)- Gas cycle, and (3) Steam cycle.

The Gasification Process, in turn, involves several major components

(Figures 8 and 9). Fuel preparation,

i.e. drying and sizing, gasification, gas turbine, and bottoming steam

cycle. These four elemental parts

are integrated to exchange heat and hereby the overall plant efficiency.

Thermochemical conversion process

can be divided into three basic steps:

1.

feedstock

preparation,

2.

pyrolysis,

3.

char

gasification (combustion).

Figure 8. Typical IBGCC Power Generation System

The gasification unit itself comprises a cylindrical, refractory lined vessel complete with cyclone for the recycling of solids. The make gas leaving this primary cyclone passes through one or more additional cyclones for further dedusting.

Figure

9. Simplified IBGCC Schematic

The feed material (which may require pretreatment) enters

the reactor on a continuous basis by means of a screw feeder, located at the

reactorfs base. The gasification

agent is being preheated by hot crude gas, and then injected via the reactorfs

bottom part. Figure 9 shows a

simplified IBGCC Schematic.

3.1.2 Feedstock

The CFB Gasification System can handle a wide variety of materials such as: wood, wood waste, bark, straw, nutshells, coconut husks, bio-sludge, peat, coal, and petroleum coke

3.1.2.1 Feedstock Preparation

Feedstock preparation (also known

as beneficiation) includes drying and sizing the feedstock to suit the

particular gasifier.

In the case of biomass fuel such as wood, wood wastes, etc.

pre-drying is usually required. Continuous

operation is achieved by the prevision of sufficient storage capacity upstream

of the dryer. First, the biomass

and residues that make up the raw materials undergo a conditioning stage to

obtain a homogeneous mixture at the reactor inflow, with reduced particle

size. The raw material can be partially

dried if the humidity is too high.

The conditioned raw material is directed to the main unit, the gas generator, which has three sections: the injection screen, the fluidized bed reactor, and the freeboard. Raw material is fed into the fluidized bed reactor, usually composed of silica sand.

3.1.3 Operation

Typically, the CFB unit operates between the area of the classical fluid bed with its defined, boiling liquid type surface, and a pneumatic lift pipe. Solids are circulating both internally – i.e. as in any classical fluid bed system – as well as externally. Particulates entrained in the gas will leave the reactor and – after gas/solids separation in s cyclone – are being recycled into the reactor. This external recycle actually became the systemfs namesake.

Injection of air or O2-enriched

air causes the sand in the CFB section to be suspended, thus favoring mass and

heat transfer. The quantity of air

or O2 enriched air required

depends on biomass composition; it is usually equivalent to 30% of the quantity

required for stoichiometric burning of the raw material. Gasification occurs at temperatures of

700 to 900 C, depending on the

physico-chemical characteristics of the raw material.

This principle of operation, which is characterized by a big gas/solids velocity difference (gslip velocityh) yields the following advantages:

q Intensive mixing of gas and solids

q Extremely high heat and mass transfer coefficients

q High gasification reaction rates (i.e. high specific throughput)

q Uniform temperature through the reactor (no hot spots), i.e. long refractory life

q Zero tart and oil production

q Environmentally highly acceptable

q Attractive economics.

Depending on product gas requirements, CFB gasification system can be operated in two ways:

q As an air blown unit for the production of low Btu gas (approximately 150 Btu/scf). This gas us suitable for boilers, limekilns, gas engines, CTfs, etc.

q With oxygen and steam as the gasification agent for the production of medium Btu gas (approximately 300 Btu/scf). This gas is suitable for the above plus, after additional treatment, for the synthesis of methanol, ammonia, SNG, etc.

The composition of the gas obtained varies according to the gasification agent (air or O2-enriched air). The producer gas is usually composed of nitrogen (of the order of 55% by volume), carbon dioxide (of the order of 16% by volume), carbon monoxide (from 12% to 30% by volume) and hydrogen (from 2% to 10% by volume). It also contains smaller percentages of light hydrocarbons, oxygen, solid particles (airborne ash), tar, and other elements depending on the particular case. After separation of residual solid particles, the tar and organic pollutants in the gas are transformed into simple organic molecules (H2 and CO).

The synthesized gas can be used in the following ways for energy recovery:

q burned as is, or in combination with natural gas, in commercial boilers to produce heat (steam);

q as a fuel, alone or with natural gas, in diesel motors to produce electrical energy;

q as a fuel, alone or with natural gas, in gas turbines to produce electrical energy, or in combined cycle (cogeneration) to produce steam and electrical energy.

3.1.4 Typical Costs

Unit size, treatment capacity, the nature of the material to be treated, and the mode of energy recovery chosen, all determine the purchase and installation costs for an integrated biomass gasification system.

The ggreen fieldh cost, including power generation system, typically varies between $1,200 and $2,000 per kW, installed. In addition, 24-hour operation of a unit with a capacity of about five (5) thermal MW requires a team of 8 to 12 people depending on the degree of automation. Expected operation costs for the unit are between $0.02 and $0.025 per thermal kilowatt produced.

4.0 Repowering

4.1

Efficiency Improvements

Undertaking

actions to improve the efficiency of existing generation will reduce emissions

of greenhouse gases. The rates

charged by any electric utility shall be such that the utility is encouraged to

make investments in, and expenditures for, all cost-effective improvements in

the energy efficiency of power generation, transmission and distribution. Improvements in efficiency of existing

generation plants can take many forms:

q Repowering, i.e., replacement of

the steam-producing equipment

q Actions to maintain and improve

heat rates such as upgrading plant instrumentation and control systems and plant

equipment, e.g., using variable speed motors for fans and pumps

q Improvements in coal preparation

and handling; and

q Efficient use of cogeneration

4.2

Repowering

As power

plants age, the efficiency of steam production equipment declines, and/or the

equipment becomes technologically obsolete, even with regular maintenance. Rather than replace aging steam production

equipment in kind, some utilities have chosen to replace it with new

technology. This process is called

"repowering" and offers the opportunity to increase the efficiency of

the process through the installation of new, improved equipment. Repowering with more efficient

equipment can reduce net emissions of greenhouse gases and air pollutants

compared to operating the original equipment. Repowering with equipment that uses lower-carbon fuels can

further reduce net greenhouse gas emissions.

By the

year 2000, about 1,200 electric utility generating units will be 40 years of

age or older. Of these, 571 are

coal-fired, 426 gas-fired, and about 164 oil-fired. Even if only a fraction of these were good candidates for

repowering, the CO2 reductions that could be obtained would be

substantial.

Repowering

can take several forms. It can

involve the replacement of the boiler with a new steam-producing facility, or

it can involve a very new steam production process involving a combustion

turbine and heat steam generator and additional generating equipment. Repowering with a natural gas-fired

combustion turbine and adding a Heat Recovery Steam Generator (HRSG) improves

overall efficiency, and often increases the electrical output of the

facility. Greenhouse gas emissions

could be reduced, as natural gas is lower in carbon than the fuel previously

used. Repowering with a combustion

turbine also has environmental benefits of more effective control of SO2,

NOx, and particulate emissions.

5.0 Economical and Social Issues

5.1

Economic

and social issues

There are many social benefits of using green biomass for energy production, such as: the creation of a market for biomass fuels, local employment opportunities for entrepreneurs and development of skills, rural stability on an environmentally sound basis, local control of reserves, and promotion of an appropriate political and economic infrastructure. On the other hand, there are worries that a widespread use of gasifiers could greatly increase the pressure in existing wood and charcoal supplies. In areas of fuel scarcity, the impact on the poor, who depend mainly on biomass fuels, could be severe.

5.2

Environmental

consideration

In comparison to oil and coal fuels, producer gas from the gasification of biomass has much lower sulfur content. This reduces SO2 emissions and lowers the risk of soil and water acidification. Producer gas has a number of adverse impacts on land-use, occupational and public health, as well as in the natural environment. However, with properly designed management systems and by following safety procedures, the impacts of using producer gas can be minimized. If these problems are taken care of, producer gas can be a good alternative to fossil fuels, and help many developing countries to improve their balance of payments by decreasing fossil fuel imports.

5.3

Advantages

One of the most attractive features of the IBGCC Power Generation technology is its potential applicability to a variety of fuels. The most pressing need for advanced gasification technology is for repowering of older coal-, oil-, and/or gas-fired boilers that typically have low efficiency and high emission levels. This technology solves the problems associated with conventional wood-burning technologies and holds great promise as a technology that can effectively dispose of biomass and wood waste while meeting strict fine particle regulations at a lower cost than current systems

IBGCC technology brings many advantages to an energy-hungry but cost-conscious world:

5.3.1 A Clean Environment.

IBGCC can meet all future environmental permitting constraints for the generation of electric power. In an IBGCC system, 99 percent of the coal's sulfur is removed before combustion, NOx is reduced by over 90 percent, and CO2 is cut by 35 percent. This environmental performance matches or exceeds that of alternate energy sources.

5.3.2 High Efficiency.

The efficiencies that will be achieved by IBGCC over the next two decades, ranging from 42 to 52 percent, contrast favorably with efficiencies of at best 34 percent offered by existing coal plants with installed flue gas desulfurization capabilities.

5.3.3 Low-Cost Electricity.

IBGCC offers low cost of electricity. The cost of IBGCC-generated electricity is now competitive with the cost of electricity produced by a conventional pulverized coal plant, and by 2010, it will drop to 75 percent of this cost.

5.3.4 Low Capital Costs.

The IBGCC plant is cost-competitive to build, at a plant construction cost of $1,200-1,500 per kilowatt right now, and $1,050 per kilowatt by 2010. Costs will drop further in subsequent years.

5.3.5 Repowering Of Existing Plants.

The components of the IBGCC system can be integrated into an existing system in modular form, allowing a user to take advantage of an existing site and its steam-generating equipment. Staged additions can be made in blocks to match one or more steam generators, and will give the resulting system two-and-a-half times the generating capacity.

5.3.6 Modularity.

The modular nature of IBGCC plant systems allows for staged additions in blocks ranging in size from 100 to 450 megawatts. As advanced turbine systems evolve, the capacity of single units will increase, and the trend will be to add large-capacity modules.

5.3.7 Fuel Flexibility.

The combined-cycle portion of an IBGCC plant can be fueled by natural gas, oil, or coal. This means not only that a plant can switch to coal from natural gas as gas becomes unavailable or unacceptably expensive, but also that an IBGCC plant can be fueled by natural gas or oil in case of unplanned events such as disruption in fuel supply. In addition, most gasifier systems can be easily adapted to different coals.

5.3.8 Phased Construction.

IBGCC systems are unique in the economical way in which they meet the demands of utility growth patterns. A first-phase installation might include only a gas turbine, operating as a simple natural-gas-fired cycle and providing about two-thirds of the plant's ultimate capacity. Addition of a steam turbine would create a combined cycle with full capacity. A third phase of installation would integrate the gasifier and gas cleanup systems when justified by low coal prices, lack of gas availability, or need for conversion to baseload capacity.

5.3.9 Low Water Use.

The water required to operate an IBGCC plant is only 50 to 70 percent of the quantity required to run a pulverized coal plant with a flue gas desulfurization system.

5.3.10 Low CO2 Emissions.

IBGCC systems offer significant reductions in CO2 emissions per unit of power produced, because their higher efficiency means that less coal must be burnt to produce each unit. When combined with the fuel cell systems of the future, IBGCC technology will be able to further reduce CO2 emissions per unit of electricity.

5.3.11 Continuous Product Improvement.

The

IBGCC system is composed of several major elements that are the subject of

ongoing advanced research and development. This development follows a planned progression toward ever

more efficient performance by the technology.

5.3.12 Reusable Sorbents.

Reusable process media remove sulfur from the coal-derived gas prior to combustion in the gas turbine. By contrast, Rue gas desulfurization of pulverized-coal and fluidized-bed power plants uses limestone, dolomite, or other sulfur sorbents that require disposal.

5.3.13 Marketable By-Products.

Waste disposal is minimal at an IBGCC plant. The sulfuric acid or elemental sulfur that is produced is a marketable product. Ash and any trace elements are melted, and when cooled, become an environmentally safe, glass-like slag that can be used in the construction or cement industries.

5.3.14 Co-Products.

In addition to producing electricity, the coal gasification process can be diverted to co-produce such products as fuels in the form of methanol or gasoline, urea for fertilizer, hot metal for steel making, and chemicals.

5.3.15 Demonstrated Success.

The IBGCC system is being demonstrated fully by multiple projects under way that not only foster competition and rapid product improvement, but also show conclusively how successfully the system operates and how it can be maintained. A full range of variations of the IBGCC process will be demonstrated: several different gasifiers, cleanup systems, repowering applications, and coals, and combinations of such elements.

5.3.16 Public Acceptability.

IBGCC sites offer an acceptable electric power generation option to a public concerned about environmental hazards and waste. Negligible plant emissions, little or no waste, safe jobs for workers, safe environments for their families, low-cost electricity for their homes, and job security based on a dependable demand for the plant's product are factors that result in acceptance by the general public.

6.0 The IBGCC Opportunity

An IBGCC power system currently produces electricity efficiently and cleanly, with only one-tenth of the emissions allowable by Federal regulations. IBGCC engineers have solved many of the problems posed by traditional coal combustion. Now the challenge is to reduce the costs of building or converting plants to use IBGCC.

With the advent of advanced power generation technologies like IBGCC, biomass is projected to remain economical fuel for electricity production. Because of its low cost and the resulting low cost of electricity to customers, biomass may be used increasingly widely throughout the world as an energy source.

When efficiency, cost-of-electricity, and environmental benefits are compared, IBGCC technology scores higher than many other advanced technologies that will be available to meet the energy needs of the next several decades, and it is likely that IBGCC will be one of the most attractive power generation technologies for the 21st century. Because of potential IBGCC improvements that will lower the cost of producing electricity, it is estimated that the IBGCC market share in the United States will increase continually to as much as 30 percent of electricity generation by the middle of the next century, resulting in 450,000 megawatts of capacity.

Outside the United States, the clean fuel technology market is projected to climb as high as $870 billion through the year 2010, and the potential market for U.S. exporters is calculated to be about $257 billion. Of this, it is estimated that $___________ may be available for new applications such as IBGCC systems.

All of this adds up to an ultra-clean, super-efficient, low-cost technology that brings strong, calculable benefits to the Nation as a whole as well as to those who invest in it as a private enterprise.

Electricity plays an essential role in U.S. and global economics, and renewable fuels could become one of the chief resources worldwide for electricity generation. Only by the use of clean fuel power generation technologies like IBGCC can we meet the world's demand for clean, affordable electricity-given the extensive coal reserves worldwide, we can do it at low cost.

The current capital cost of building an IBGCC ggreen fieldh power plant is as low as $1,500 per kilowatt. Following planned commercial-projects, this cost is expected to drop to $1,200 per kilowatt, and it is estimated that it will drop further, to $1,050, by 2010, 75 percent of the cost of electricity from one of today's conventional power plants.

7.0

Summary

Gasification

processes have begun to gain attention throughout the world. Their uses include:

1.

Production

of hydrogen and methanol from carbon-containing materials such as municipal

solid wastes, agricultural wastes, forest residues, etc. for use

in high-tech fuel cell

2.

Gaseous fuel

generation, which can be utilized instead of natural gas

3. Power generation (gas turbines, combined

cycle)

Integrated Biomass Gasification Combined Cycle (IBGCC) systems replace the traditional combustor with a gasifier and gas turbine. Exhaust heat from the gas turbine is used to produce steam for a conventional steam turbine. The gas and steam turbines operate together as a combined cycle.

It is

believed that in the near future, the use of gasification to convert waste materials

into ready-to-use fuel could literally solve several environmental problems at

the same time.